Products

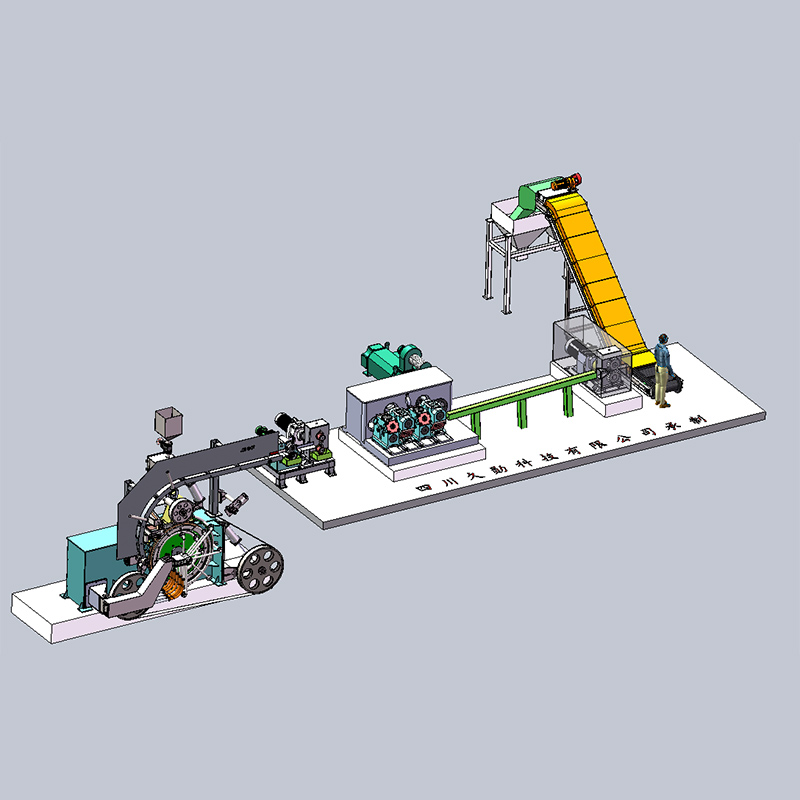

Wheel Type Aluminum Billets Continuous Casting Line

Process Flow

Melting(Holding) furnace(with mixer)→Online degassing and filtration→Four-wheel type continuous casting machine→Active straightener→Code marking machine→Hauling machine→Shearer→Cooling device→Roller conveyor→mechanical/robot stacking →manual/automatic strapping

Main Characteristics

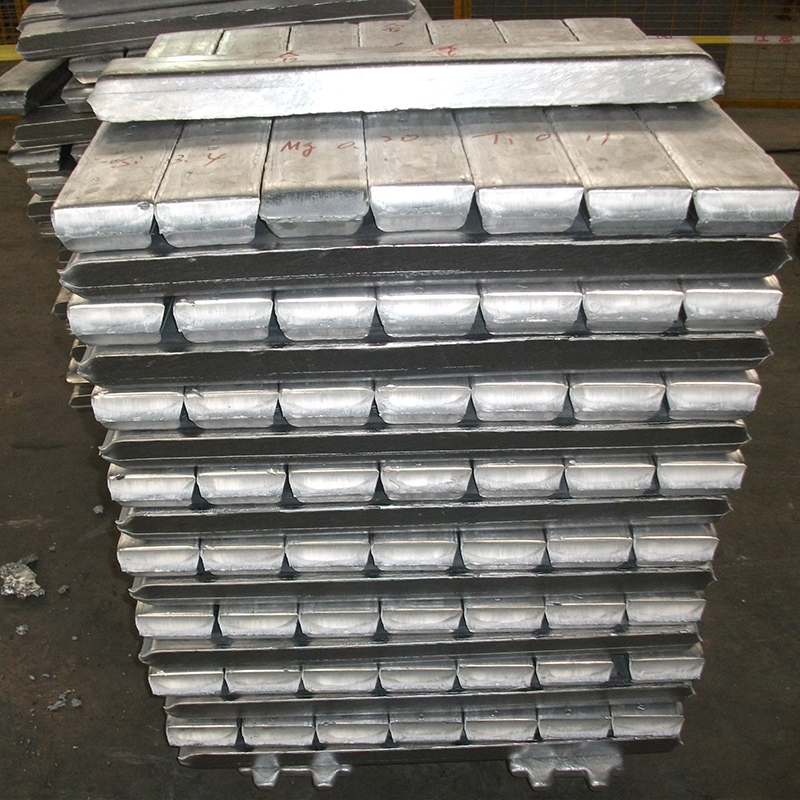

1. Fine and uniform grain structure, stable quality for the ingots/billets

2. High output, high degree of automation and intelligence, safe working environment

3. Simple process, small investment, short production procedures, and extremely high cost-effective

4. The surface of the ingot is flat and smooth, without casting defects like porosity, slag inclusion, burrs and cracks, etc.

5. The ingot can be made into T-shaped or wave-shaped according to customer’s requirement.

6. This is an innovative technology and technic, which has replaced the old technics of horizontal die casting and vertical casting.

Technical Parameters

|

Aluminum (Alloy) billets Casting Line |

||

| Machine type |

JXKJ5000-5 |

MRS5000-10 |

| Capacity |

≥5t/h |

≥8-10t/h |

| Casting ingot sectional area |

5290mm2 |

5290mm2 |

| Crystallizing wheel dia. |

Ф2100㎜ |

Ф3100㎜ |

| Speed |

150-240mm/s |

150-240mm/s |

| Finished product |

A356 ,etc |

A356, etc |

| Casting ingot shearing length |

600-750mm (can be set as per customer's requirement) |

600-750mm (can be set as per customer's requirement) |

| Electric control mode |

PLC+ HMI |

PLC+ HMI |

Display