-

2-roller type Aluminum and aluminum alloy Rod CCR Line

Application: This series of aluminum alloy CCR line belongs to the typical and high configuration to meet the individual demand of customers.

Raw material: Primary aluminum ingots/sow/ electrolytic aluminum molten/aluminum scrap from wire or cable

Fuel: NG/LPG/LDO/FO/COAL GAS

-

Aluminum Refining Equipment

Function:

It is used for stirring the aluminum alloy molten, and mix all metal elements sufficiently to get a more uniform temperature and separate the slag out, also can reduce the labor cost and improve work efficiency. It has Permanent Magnet Stirrer and Electromagnetic Stirrer; the customer can choose according to different demand.

-

Aluminum Alloy Ingots Induction Heating Furnace

Application

The medium frequency induction heating furnace is installed between automatic shearer and continuous rolling mill, the main function is heating the aluminum alloy bar, so as to meet the temperature of the technology required before rolling.

-

Natural Gas De-oxidation system

NG Reduction system

This system is used for the copper reduction (de-oxidization). As usual, according to our traditional technology, we use the fresh trees for reduction, however, some countries cannot provide large quantity of trees, so we recommend to adopt the Natural Gas for reduction, so that can reduce the trees quantity, but can not 100% instead of trees, because need to ensure the reduction effect.

-

Pure Oxygen Combustion System

Application:

It is a new energy-saving technology developed and designed by our company in combination with the characteristics of industrial furnaces.

It is composed of burners, fuel decompression regulation system, oxygen decompression regulation system and controlling system.

At present, this technology has been used for copper scrap refining furnaces, more than 50% natural gas can be saved.

-

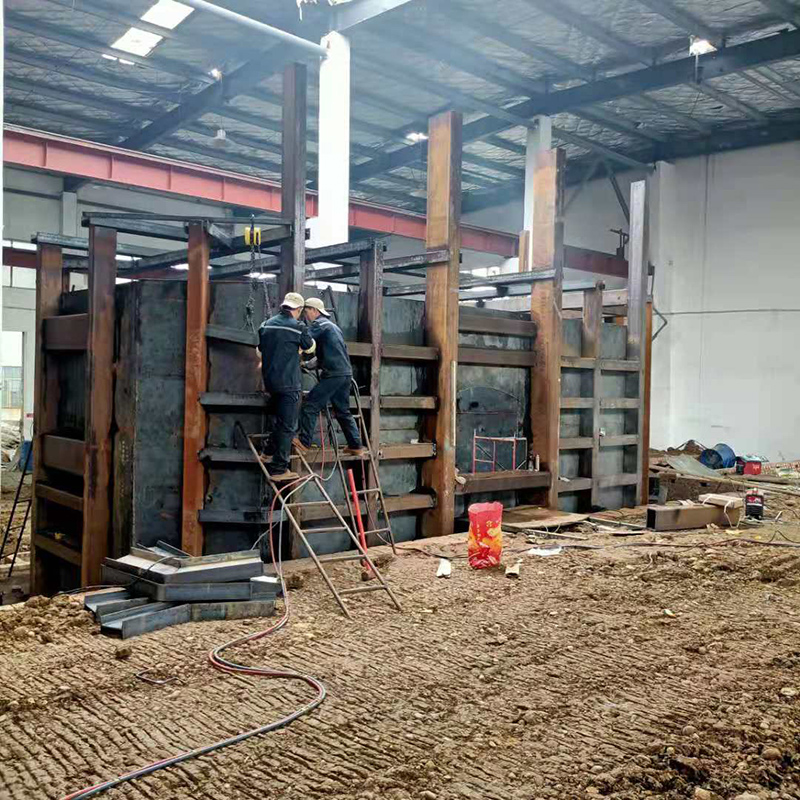

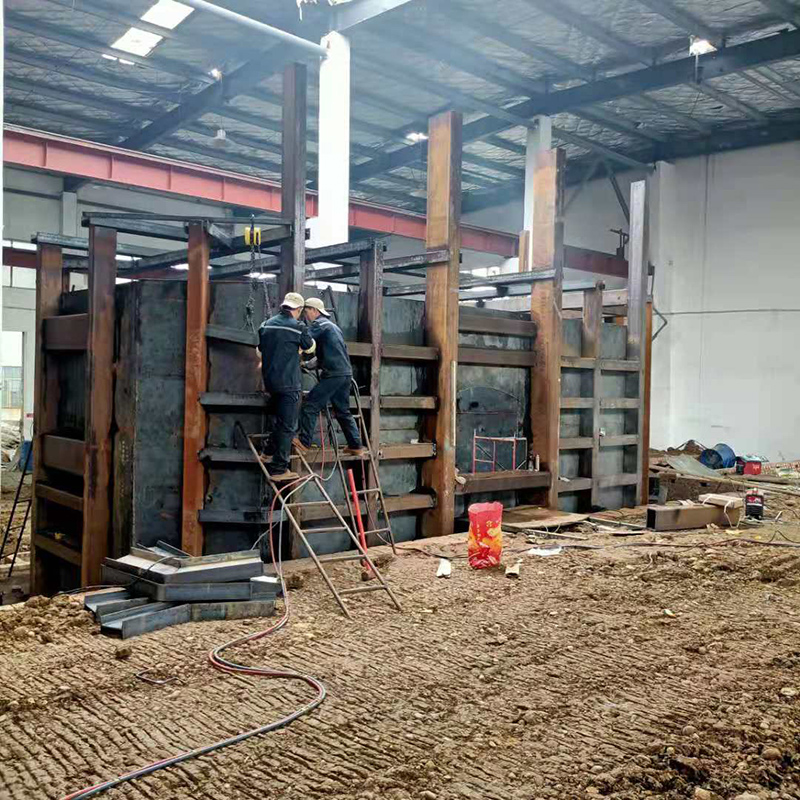

Copper Scrap Stationary Refining Furnace

ApplicationThe Stationary Refining (reverberatory) furnace is widely used for copper scrap smelting. Because of good adaptability to raw materials, it also can be used as anode copper smelting. The refining furnace has low maintenance rate, less equipment input, rapid convergency, and the capacity can be designed as the customers ‘need (15T-120T), the refining technology is easier than other technology, so it is still adopted by most users.

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap

-

Oxygen Free Copper Rod Up-casting Line

Application :

To produce the oxygen free copper rod, tube, flat billets and other profile products.

The oxygen free copper rod has high conductivity and low oxygen content, and comparing with other copper rod production technology, the up-casting line has obvious advantages, such as less budget, less occupied area, wide products range, non-pollution, etc.

Raw materials: cathode, copper granule, 1st level copper scrap

Capacity: 2000T – 15000T/ year

Rod dia: φ8mm-φ30mm

Fuel: electricity

-

Copper Rod Cold Mill

According to the requirements of customers and market products, our company has developed a series of cold rolling mills used in the wire and cable industry. According to purpose, it can be divided into metal cold rolling mill and cable cold rolling mill; according to machine type, it can be divided into 2-roller cold rolling and 3-roller cold rolling; according to drive mode, it can be divided into integral drive and individual motor drive.

The cable cold rolling mill is a new type machine developed by our company in 2017, it is mainly used for the production of railway seamless alloy links up grounding wires and BTTZ mineral insulated fireproof cables.

-

Copper and Aluminum Coil Packing Machine

Function:

Instead of manual strapping or bundling, our company can design and manufacturing the following automatic strapping machine.

-

Aluminum Rod Rewinder (Vertical Type)

Application: The equipment is used for aluminum rod rewinding in order to make the coil compacted.

-

Furnace Exhaust Environmental Protection System

Environment Protecting System Description:

The environment protecting system is used for removing mass dust and harmful discharged exhaust gas from the furnace smoke channel, especially the SO2 and CO2 in the melting process, greatly upgrade the enterprise economic benefit and social effect, and achieve the environmental protection function effectively.

We can design and manufacture the system according to the customer’s pollutant, emission standards and industry standards to meet the differentiated needs of customers. The common 2 types are: Pulsed Jet Cloth Filtering System, Cyclone & Water Membrane Dust Removal System

-

Radiator Recycling line

The Radiator Recycling Machine will be used for disassembling the waste radiator which are difficult to disassemble manually or the manual disassemble cost is too much high. After the professional processing, it can obtain renewable resources. The whole process is carried out in the negative pressure. The operator should charge the materials and select the large pieces of iron or large diameter screws, shaft material and other hard materials out, then enter the 1st stage roughing crusher and 2nd stage fine crusher in order to make the copper, iron, aluminum fallen off, finally adopt the strong magnetic roller and air separator to separate the Al, Cu. Fe. In the process of crush and sorting, a pulse dust removal system is equipped to solve the problem of dust discharge effectively.