Products

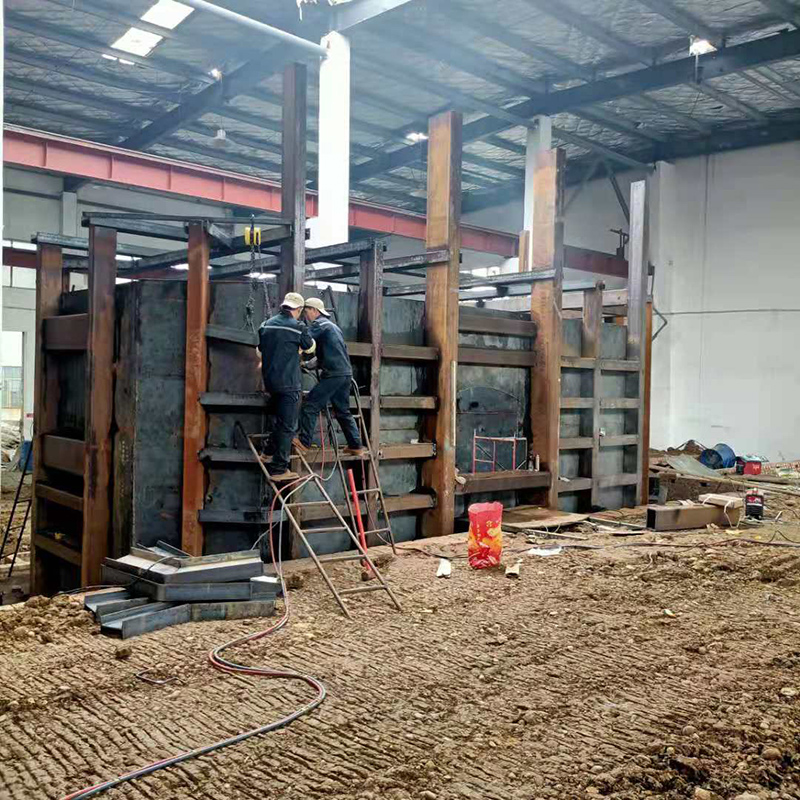

Copper Scrap Tilting Refining Furnace

Characteristics

1.Super adaptability for raw materials, both solid and molten material can be used

2.Easily charging, evenly material distributed, fast melting speed

3.Reasonable furnace chamber with tilting mechanism, better heat transfer effect and use ratio.

4. High degree of mechanization, compressed air for oxidization, NG for de-oxidation

5.Reasonable tilt angle is good for Oxidation air spread in the molten, high degree of oxidation

6.Effectively reduce black smoke pollution rates

7.Copper molten outlet is flexible equipped with casting machine

8.High degree of automation, easily and safety for operation and maintenance

Technical Parameters

|

No |

Item | Parameters | Note |

|

1 |

Capacity | 3T-60T/batch | According to customers' requirements |

|

2 |

Fuel | NG/LPG/LDO/FO/COAL GAS | Burners maybe different |

|

3 |

Raw Materials | 100% Copper Scrap | Barley/Berry/Birch/enameled wire /Candy/Clove |

|

4 |

Charging position | Furnace Roof / Furnace Side | Design according to furnace capacity |

|

5 |

Burners | No of burners according to furnace capacity | Domestic independent brand, imported brand can be adopt |

|

6 |

Combustion System | High Temperature combustion system/ Pure Oxygen combustion system | Pure combustion system is only suitable for NG and LPG , can save fuel 40% at least |

|

7 |

Blower | According to the furnace capacity | |

|

8 |

Main Refractory Materials | Mg Al Cr brick/ Spinel Mg Al Cr brick | Refractory Material is one of main factor of Furnace Life |

|

9 |

Furnace door lifting | mechanical open/close | |

|

10 |

Oxidation media | Compressed Air | Oxidation media by Compressed Air |

|

11 |

Reduction method | Natural gas | Reduction by Natural gas |

Display