-

25-48t/h High Speed Cathode Copper Rod Continuous Casting and Rolling Line

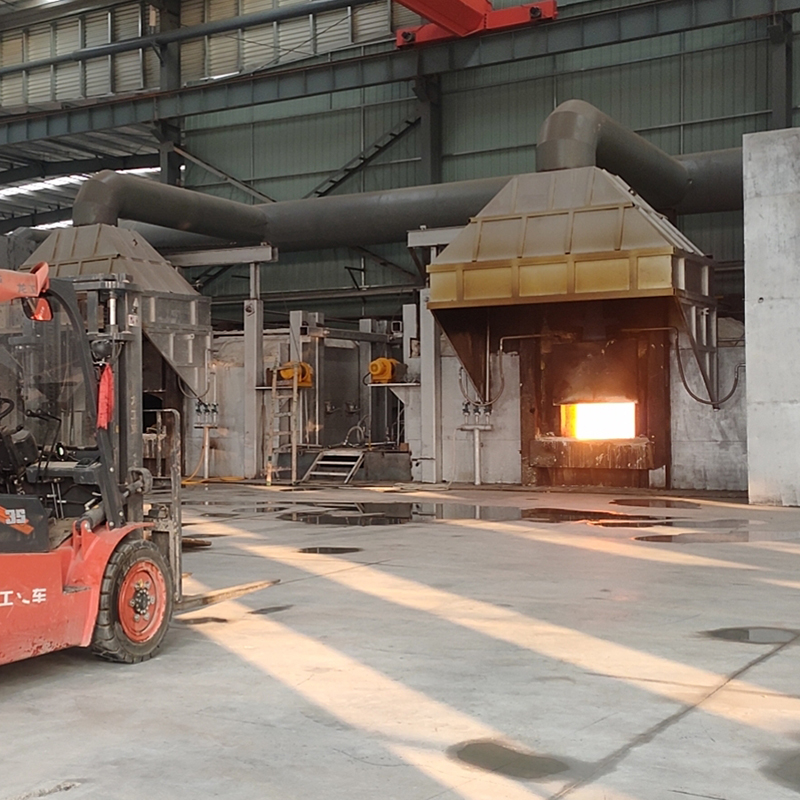

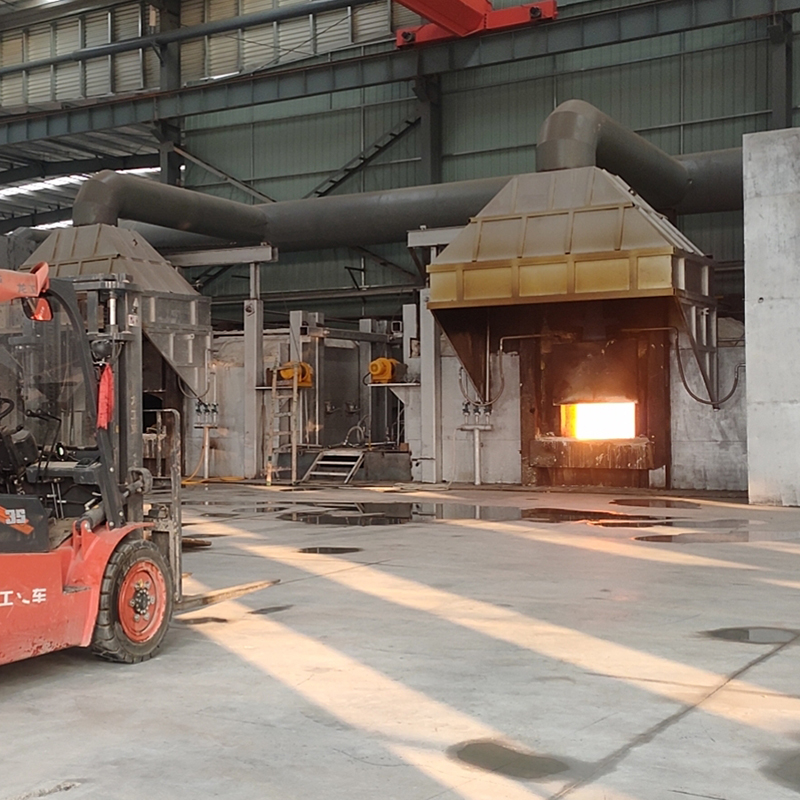

Application: High speed Full-2 Roller Type Copper Rod CCR line is used for producing high quality low oxygen copper rod for electrical purpose.

We design this line combined with the world’s advanced SCR and Morgan technology, but we improve many systems and try to help the customer to reduce investment to the maximum extent.

Fuel: NG, LPG

Raw Material:

Copper Cathode Electrolytic Grade A is required, the copper purity should be 99.975%-99.99%, the 1st grade scrap copper (barely) can be mixed, but the percentage is better no more than 10%-15%.

-

2-roller Type Copper Rod Continuous Casting and Rolling Line

Application: This production line is used for producing φ8mm copper rod. However, the rolling mill is composed of roughing mill and finishing rolling, and the mill type is full 2-roller type driven by individual motors.

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap, Cathode

1) Using red copper scrap as the raw material, the mixture ratio is as the below:60% of the 1st grade copper adds 40% of the 2nd grade copper.

2) If adopt the cathode as raw materials, the Copper Cathode Electrolytic Grade A is required, the copper purity should be 99.975%-99.99%, the 1st grade scrap copper (barely) can be mixed, but the percentage is better no more than 10%-15%.

3) The raw material mentioned above is only for reference, it depends on the requirements of copper rod quality and technology.

-

3-roller Type Copper Rod Continuous Casting and Rolling Line

Application: This production line is used for producing φ8mm copper rod. It has simple structure, high production efficiency, low energy consumption, excellent product quality and high return on investment.

Fuel: NG, LPG, LDO, FO, COAL GAS

Raw Material: Copper Scrap, Cathode

1) Using red copper scrap as the raw material, the mixture ratio is as the below:60% of the 1st grade copper adds 40% of the 2nd grade copper.

2) If adopt the cathode as raw materials, the Copper Cathode Electrolytic Grade A is required, the copper purity should be 99.975%-99.99%, the 1st grade scrap copper (barely) can be mixed, but the percentage is better no more than 10%-15%.

3) The raw material mentioned above is only for reference, it depends on the requirements of copper rod quality and technology.