Products

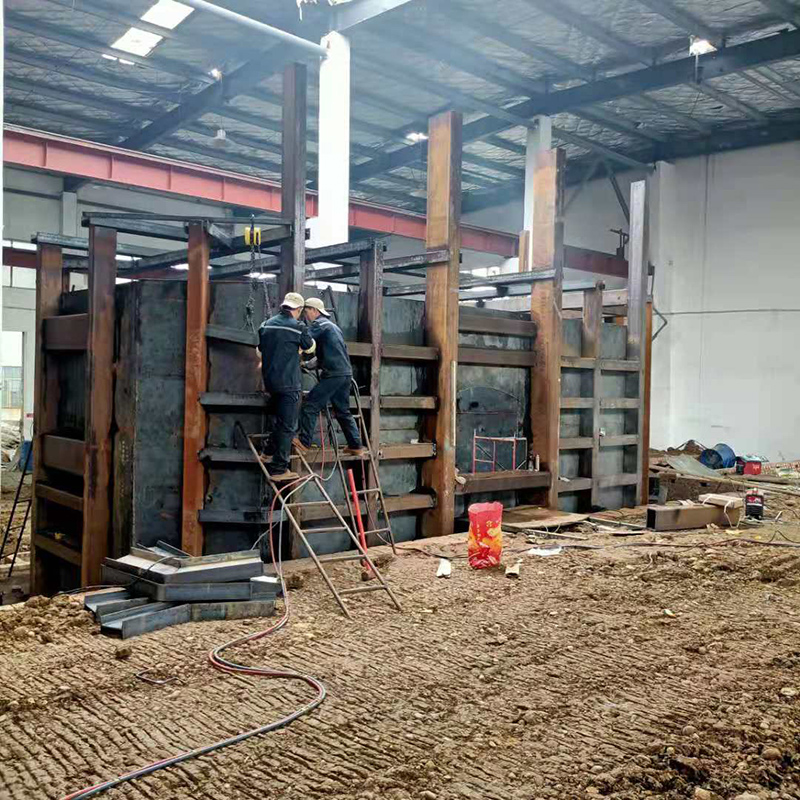

Cathode Shaft Melting Furnace and Tilting Holding Furnace

Characteristics

1.Capacity is flexible, shaft furnace melting rate is from 8t/h to 48t/h, holding furnace is from 8T to 25T.

2.From the cold status to be molten, it needs around 2 hours, while stop the furnace only need about 3-5 minutes.

3.The raw material can be: cathode plate, copper rod scrap coil, bare copper wire, and internal copper scrap from CCR.

4.Setting with the safety device, when the gas pressure is too high or too low, the power or combustion fan failure, the gas can be cut off immediately.

5.Reliable premixed combustion system makes the oxygen content of copper molten more stable, easy to control and save the energy.

6.The key components adopt the USA brand (shut-off valve for safety control, Air/gas ratio proportional valve and mixer, etc.)

Display