Products

Anode Casting and Copper Electrolysis Workshop

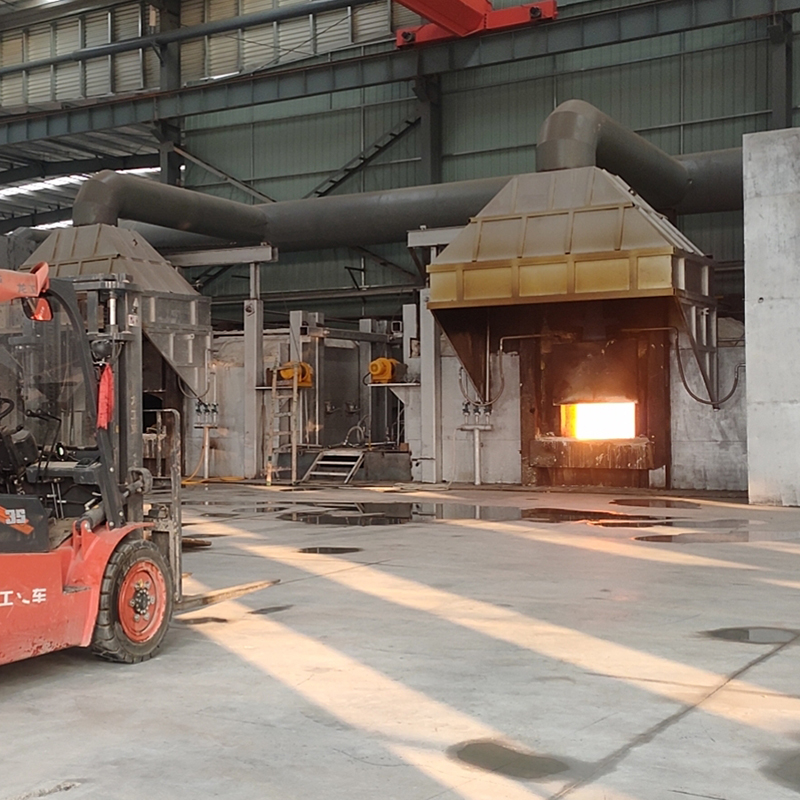

I. Copper Anode Melting & Casting Line

Description

The Copper Anode Plate Disc Casting Machine equipped with melting furnace are used for producing the Anode sheet, the anode sheet size can be specified by the user. According to the configuration, the machine can make manually and automatic quantitative casting, and adopt industry PLC frequency conversion integrated control. The whole system has high degree of automation, smooth operation, and the finished product has no crimping and casting fin.

Process Flow

Qualified Copper Molten → Launder→ Upper Tundish →Lower Tundish→ Disk Casting Machine→ Cooling Device → Anode Jacking Device→ Anode Plates Collecting Device → Finished Product.

II. Copper Cathode Electrolytic system

Application

Cathode plate electrolysis system is used for transfer copper anode containing certain impurities into high quality copper cathode plate. Due to the whole process by electrolysis process, we can call it “electrolytic copper”. The final products should be conformity with the standard of GB/T467-1997 (Cu-CATH-1) and (Cu-CATH-2). The whole system is joint designed and manufactured by our company and one Chinese well-known state-owned copper factory, the annual capacity can be from 6,000T to 100,000T, which has advanced technology and lower energy consumption. We can provide the whole project designation and technology service according to the customer’s requirements.

Composition

Anode preparation machines, stripping machine, residual cleaning machine, Electrolytic crane and spinner, Cathode grinding machine, Permanent cathode, electrolytic bath, controlling system, Production tank rectifier, de-coppering Circulation electrolytic bath, boiler room, Oil-fired steam boiler, air compressor station, LPG station, LPG mixer, transportation facilities.

Main Designing Parameters

|

No. |

Technical Point |

Parameter |

|

1 |

High purity copper cathode |

Cu≥99.9935% |

|

2 |

Annual/working days |

350d |

|

3 |

Copper cathode recovery rate |

99.80% |

|

4 |

Residual rate |

17% |

|

5 |

Bath voltage |

0.25~0.3V |

|

6 |

Cathode plate size |

1010×810mm |

|

7 |

Weight/piece |

≈100 kg |