Products

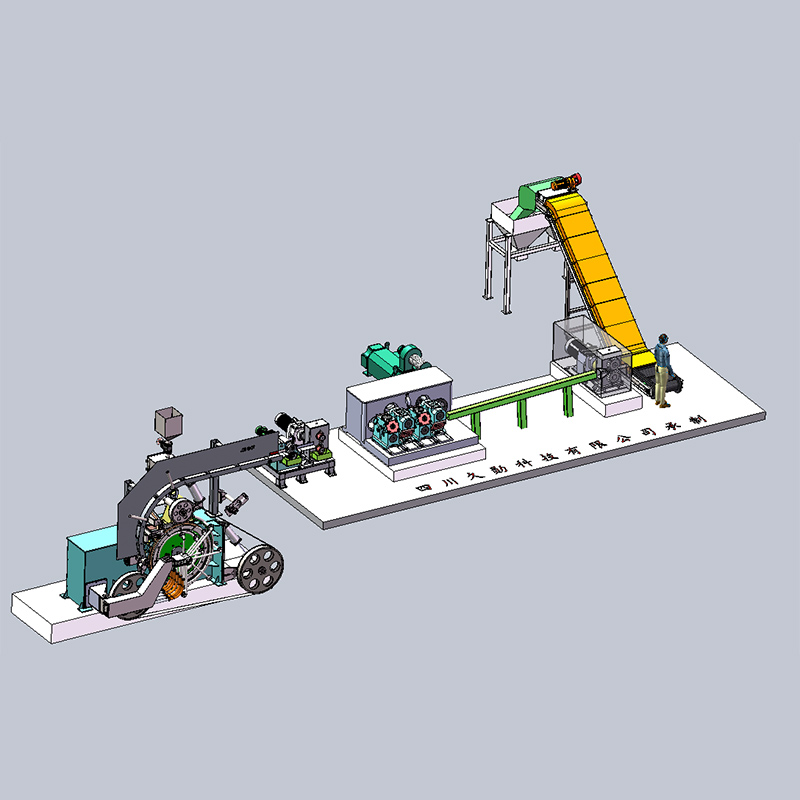

Aluminum Billets/ Ingots Casting Line

Process Flow

Melting-Holding (or refining furnace)—Launders—Tundish—casting distributor—transmission chain—water spraying and cooling—Mechanical/ Robot stacking machine—manual/ automatic strapping

Display