Products

3-roller Type Copper Rod Continuous Casting and Rolling Line

Process Flow

Cathode Shaft Melting Furnace →Holding Furnace/ Scrap Flat Refining Furnace → Casting Machine → Upward hauling, shearer, Straightening, edge shaving & brushing → Continuous Rolling → Rod Coolant, Cleaning, Recovery (wax coating) → Coiling Baskets Drop Coiler/ Coiling Hydraulic Take-up

Production Line Selection

|

φ8mm Low Oxygen Copper Rod Continuous Casting & Rolling Production Line |

|||||

|

No |

Model |

Capacity |

Sectional Area |

Rolling Mill Type |

Main Machine Installed Power |

|

1 |

JX1600/8-255/8 D |

5-8t/h |

1200㎜² |

4+4 |

400KW |

|

Traditional 2 roller + 3 roller |

|||||

|

2 |

JX1810/4+6+2/8 D/H |

12-16t/h |

2330㎜² |

4+6+2 |

660KW/700KW |

|

Traditional 2 roller + 3 roller |

|||||

|

3 |

JX2100/4+6+2/8 D/H |

17-18t/h |

2330㎜² |

4+6+2 |

880KW/920KW

|

|

Traditional 2 roller + 3 roller |

|||||

|

4 |

JX 2100/14-255/8 D/H |

18-20t/h |

3200㎜² |

6+6+2 |

830KW/860KW |

|

Traditional 2 roller + 3 roller |

|||||

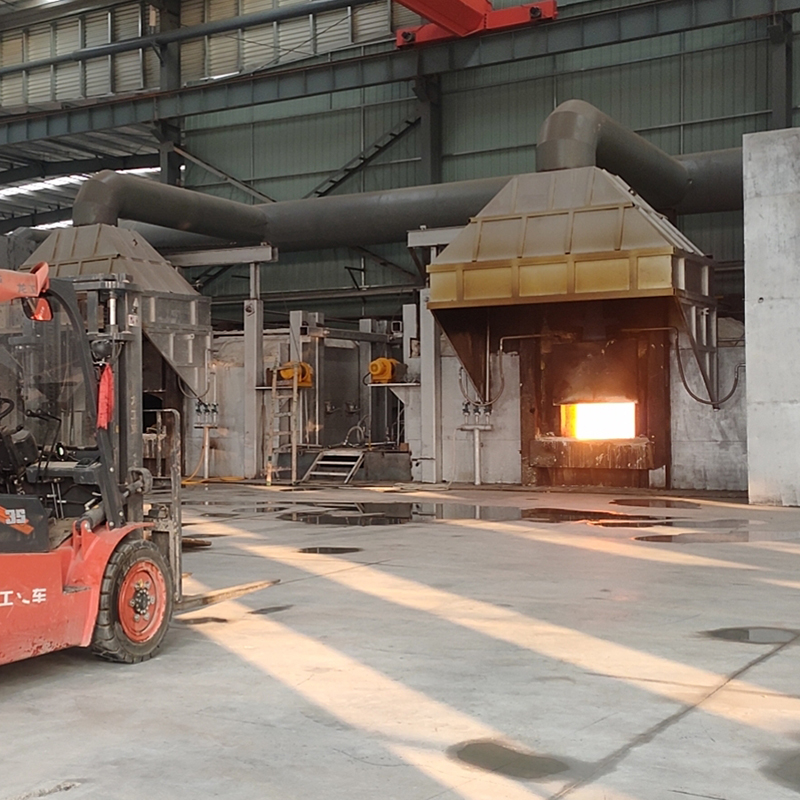

Display