Products

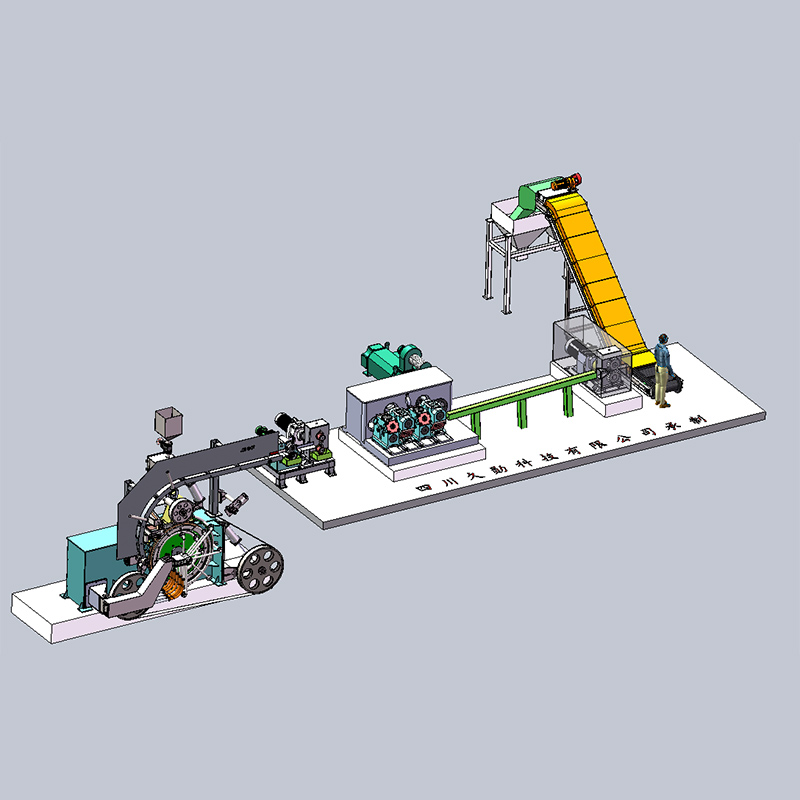

3-roller type Aluminum and aluminum alloy Rod CCR Line

Process Flow

Melting → Refining (Alloy proportion, stirrer, slagging, holding) → On-line degassing& filtration → Horizontal casting → Casting bar pretreatment (forward pinch roll, shearer, straightening) → Induction heater→ Continuous rolling→ Quenching →Rod Coiling

Advantages of New Design 2-roller Type Rolling Mill

1. The designation is similar like Morgan mill, also can adopt Morgan Mill Type.

2. The rollers are outside of mill housing, it is easy for assembly and disassembly, the life of the roller would be longer

3. The rollers can adopt H13 or TC materials.

4. The mill driven adopt individual drive, AC or AC servo motors.

5. Adopt the oil-water separation design

**The Rolling mill gears are Lubricated by gear oil

**Bearings of rolling stands are lubricated by mechanical oil

**Rollers are lubricated by emulsion oil

6. Can produce high strength alloy, such as 5 series alloy 5154, 5356

7. Can increase the capacity for pure aluminum and common alloy (6000/8000 Series alloy) . The max. capacity can be 7.5t/h-8T/H.

Production Line Selection

|

Aluminum (Alloy) Rod Continuous Casting & Rolling Line |

||||||||

|

NO |

Model |

Application |

Specification |

Capacity |

Sectional Area |

Rolling Mill Type |

||

|

1 |

JX2300/9.5-3U+10Y |

A2/ A4/A6/A8/1350 EC ROD |

7.6mm/9.5mm/12mm/15mm |

2.0t/h-3.5t/h |

1200mm2/2000mm2 |

12 or 13 rolling mills |

||

|

Roughing mill : 2 roller type, individual drive Finishing rolling: 3 roller type, Central drive |

||||||||

|

2 |

JX2300/9.5-300/4-255/8 |

4.0t/h-8t/h |

2300mm2 |

12 rolling mills |

||||

| Roughing mill : 2 roller type, individual drive Finishing rolling: 2 roller type, Central drive/ individual drive | ||||||||

|

3 |

JX6500/9.5-12U-M |

10.0t/h-12.0t/h |

6500mm2 |

11 or 12 stands (Morgan Mill Type) |

||||

|

Full New Type2 Roller, oil-film bearing, individual drive |

||||||||

Display