Products

25-48t/h High Speed Cathode Copper Rod Continuous Casting and Rolling Line

Advantages and Improvement

1.The whole line has high automation.

2.The life of all parts is very long

3.The quality of the low oxygen rod is very excellent

4.The monitoring and the data analysis system can help the customer to achieve the futures analysis

5.We are not copying, but make the line has more flexible configuration according to the customers’ budget and products.

Process Flow

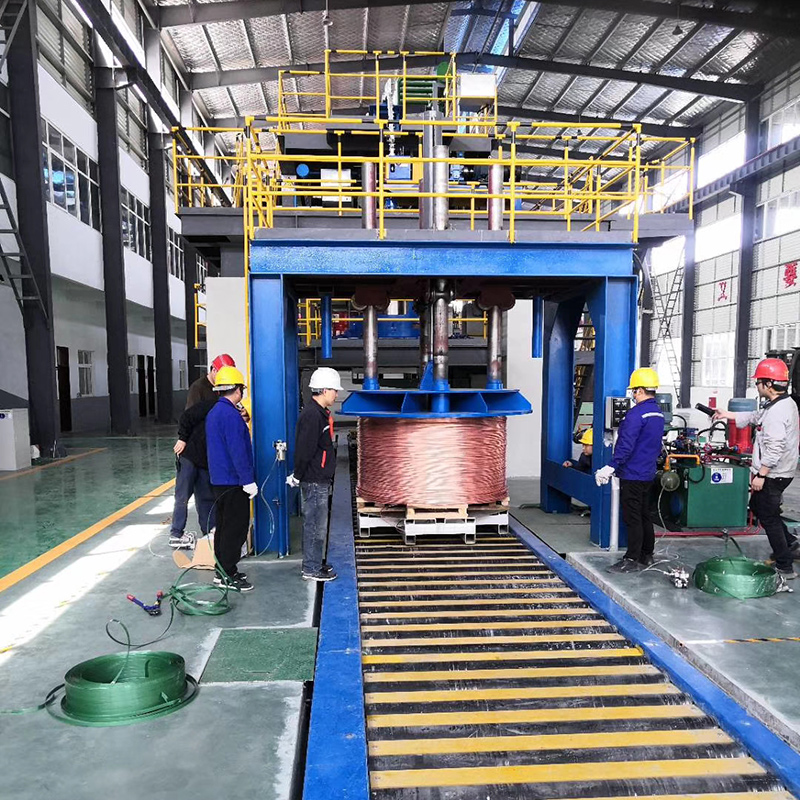

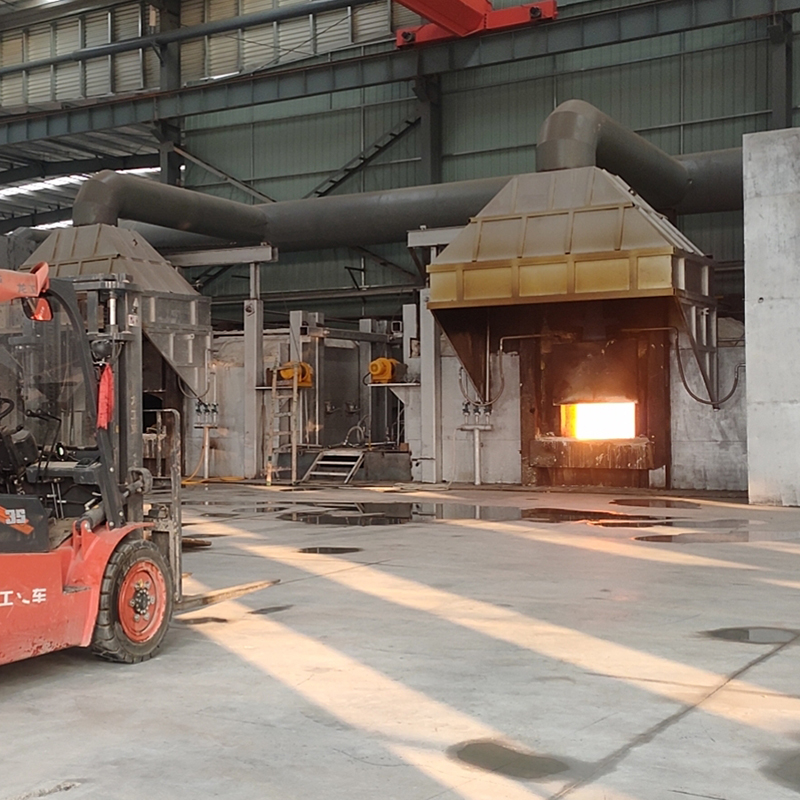

Cathode → Loading system → Shaft Melting Furnace → Heating type upper launder → Tilting slagging tank → Tilting Holding Furnace → heating type lower launder → heating type tundish → Casting with AMPS → Upward Pinch Roll &Rotary Shearer → Waste Bar Discharge → Movable Hydraulic Cutter → Bar Preparation Machine → Cogging Mill (Equipped according to sectional area) → Roughing Mill → Intermediate Rotary Crop Shearer and Discharge → Finishing Mill → Rod Delivery, Cleaning and Recovery System → Rod Backward Pinch Roll and Coiling System → Hydraulic Take-up System→ Pallet Delivery and Stacking → Coil Compactor → Coil Auto-bundling Machine → Online Weighting & Labeling → Manual/ auto-film wrapping Machine → Delivery to SWMS (Intelligent warehouse)

Production Line Selection

|

8mm High Speed Copper Rod Continuous Casting & Rolling Production Line |

|||||

|

No |

Model |

Capacity |

Sectional Area |

Rolling Mill Type |

Main Machine Installed Power |

|

1 |

JXLG 3800 |

20-25t/h |

3800㎜² |

2+8 |

1550KW |

|

Full 2 Roller, oil-film bearing Driven by individual motors |

|||||

|

2 |

JXLG 5500 |

30-35t/h |

5429㎜² |

1+2+8 |

2000KW |

|

Full 2 Roller, oil-film bearing Driven by individual motors |

|||||

|

3 |

JXLG 6600 |

35-40t/h |

6580㎜² |

1+4+8 |

2800KW |

|

Full 2 Roller, oil-film bearing Driven by individual motors |

|||||

|

4 |

JXLG 8200 |

40-45t/h |

8200㎜² |

1+4+8 |

3200KW |

|

Full 2 Roller, oil-film bearing Driven by individual motors |

|||||

Display