Products

2-roller Type Copper Rod Continuous Casting and Rolling Line

Advantages

1.The rolling mill belongs to the independent research and development products of our company.

2.The rolling mill only need very fewer spare parts, only need to change rollers and guides.

3.The rolling gap can be adjusted online, and life of the roller is very long.

4.The operation of the mill is easier.

5.The rolling mill adopts emulsion and lubricant separation system.

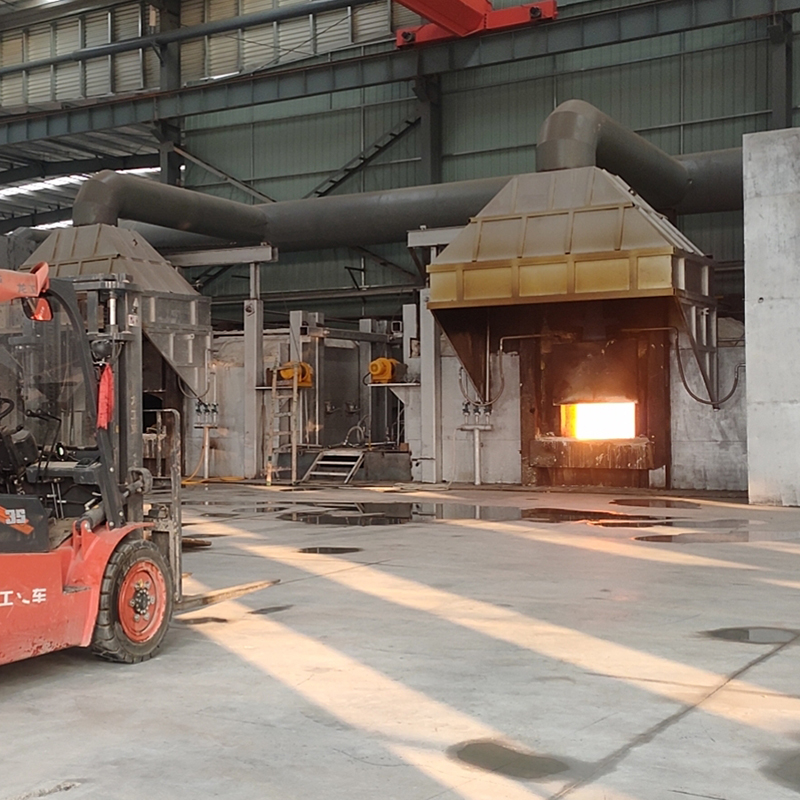

Process Flow

Cathode Shaft Melting Furnace →Holding Furnace/ Scrap Flat Refining Furnace → Casting Machine → Upward hauling, shearer, Straightening, edge shaving & brushing → Continuous Rolling Mill → Finishing Mill → Rod Coolant, Cleaning, Recovery (wax coating) → Coiling Baskets Drop Coiler/ Coiling Hydraulic Take-up

Production Line Selection

|

8mm Low Oxygen Copper Rod Continuous Casting & Rolling Production Line |

|||||

|

No |

Model |

Capacity |

Sectional Area |

Rolling Mill Type |

Main Machine Installed Power |

|

1 |

JX1200/8-200/8-D |

5-8t/h |

1200㎜² |

2 roller type new design by single main motor |

400KW |

|

2 |

JX2330/8-300+250/11-H |

12-20t/h |

2330㎜² |

Roughing Mill: NO.1-NO.3 Finishing Rolling: NO.4-NO.11 By individual motors |

1200KVA |

Display