Products

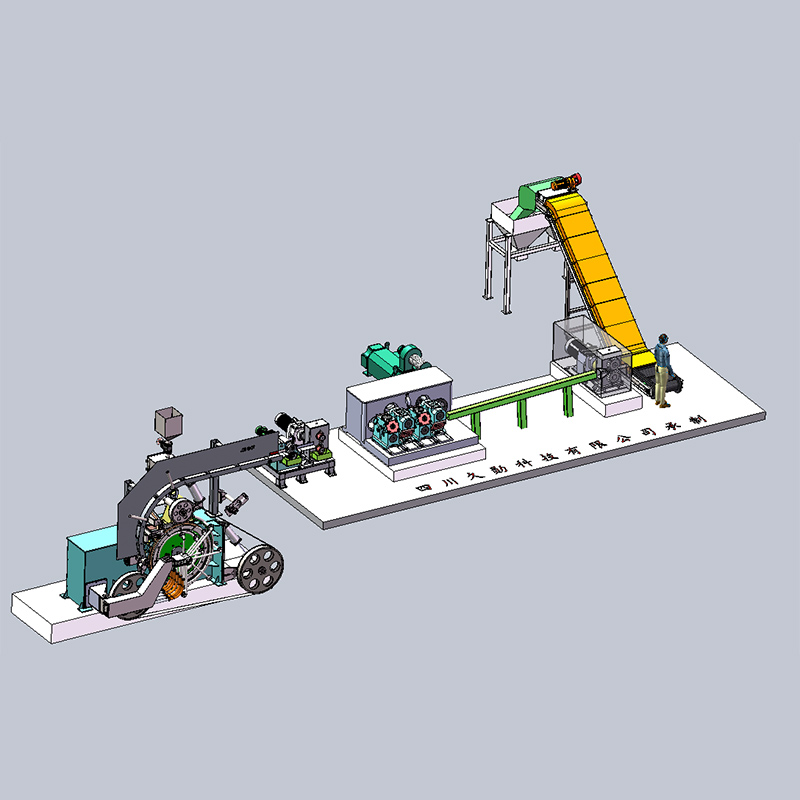

2-roller type Aluminum and aluminum alloy Rod CCR Line

Advantages and Improvement

1.The whole line has high automation.

2.The life of all parts is very long

3.The quality of the low oxygen rod is very excellent

4.The monitoring and the data analysis system can help the customer to achieve the futures analysis

5.We are not copying, but make the line has more flexible configuration according to the customers’ budget and products.

Process Flow

Melting → Refining (Alloy proportion, stirrer, slagging, holding) → On-line degassing& filtration → Horizontal casting → Casting bar pretreatment (forward pinch roll, shearer, straightening) → Induction heater→ Continuous rolling→ Quenching →Rod Coiling

Production Line Selection

|

Aluminum or Aluminum Alloy Rod Continuous Casting & Rolling Line |

|||||

|

Model |

Application |

Specification |

Capacity |

Sectional Area |

Rolling Mill Type |

|

JX1600/9.5(12,15)-255/15(13,11) |

A2/A4/A6/A8/ EC 1350 8030/8176/6201/6101 |

9.5mm/12mm/15mm |

2.6t/h-6.0t/h |

2340㎜² |

15 stands |

|

NO.1-NO.15: 3 rollers |

|||||

|

JX2500/9.5-255/14 |

9.5mm/12mm/15mm |

3.0t/h-5.5t/h |

2340㎜² |

14 stands |

|

|

NO.1- NO.2: 2 rollers NO.3-NO.14: 3 rollers |

|||||

|

JX3200/9.5-255/14 |

9.5mm/12mm/15mm |

3.5t/h-7.5t/h |

3200㎜² |

14 stands |

|

|

NO.1-NO.6: 2 rollers NO.7-NO.12: 3 rollers NO.13-NO.14: 2 rollers

|

|||||

|

JX2500/9.5/7.6-255/16 |

7.6mm/9.5mm/12mm/15mm |

3.5t/h-6.0t/h |

2400㎜² |

16 stands |

|

|

NO.1- NO.2: 2 rollers NO.3-NO.16: 3 rollers |

|||||

Display